- Heat Exchange Coils

- Dispensing

- Brewing

- Tubing

- Fittings & Clamps

-

Recently Viewed

You have no recently viewed items.

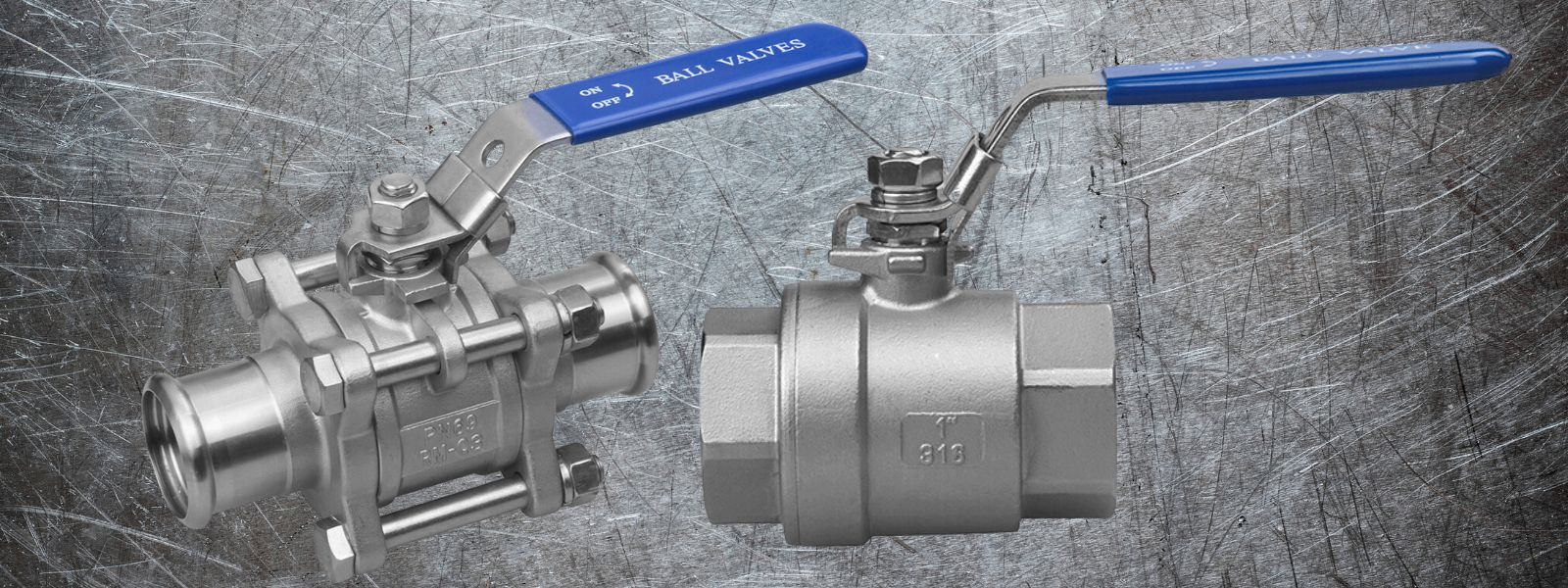

How 316 with a .028-inch wall stainless steel can be used in Water Control Systems

Type 316 stainless steel with a .028-inch wall thickness is widely used in water control equipment because of its excellent resistance to corrosion, especially in harsh or chloride-rich environments such as saltwater or areas where de-icing salts may be present. Here’s how it’s typically applied:

-

Corrosion Resistance: The high molybdenum content in Type 316 stainless steel offers superior corrosion resistance compared to Type 304, making it suitable for environments where water might be contaminated with salts, minerals, or chemicals. This is especially important for parts submerged or in constant contact with flowing water, as it minimizes corrosion and extends the equipment's life.

-

Thin-Wall Applications: The .028-inch wall thickness is relatively thin, making this steel well-suited for applications where weight savings or limited space is important, yet strength and durability cannot be compromised. This makes it ideal for smaller components like tubes, seals, or linings within water control valves and fittings.

-

Temperature and Pressure Stability: Type 316 stainless steel can withstand high pressures and temperatures, which is beneficial in water control systems that experience varying pressure or temperature conditions.

-

Low Maintenance: Equipment made from Type 316 stainless steel typically requires less maintenance than other materials, as it resists pitting and cracking over time. This property is advantageous for water control equipment that is installed in difficult-to-access areas or underwater.

In short, Type 316 stainless steel with a .028 wall thickness is used in water control equipment to ensure long-lasting performance, corrosion resistance, and structural integrity in demanding environments.

- Choosing a selection results in a full page refresh.